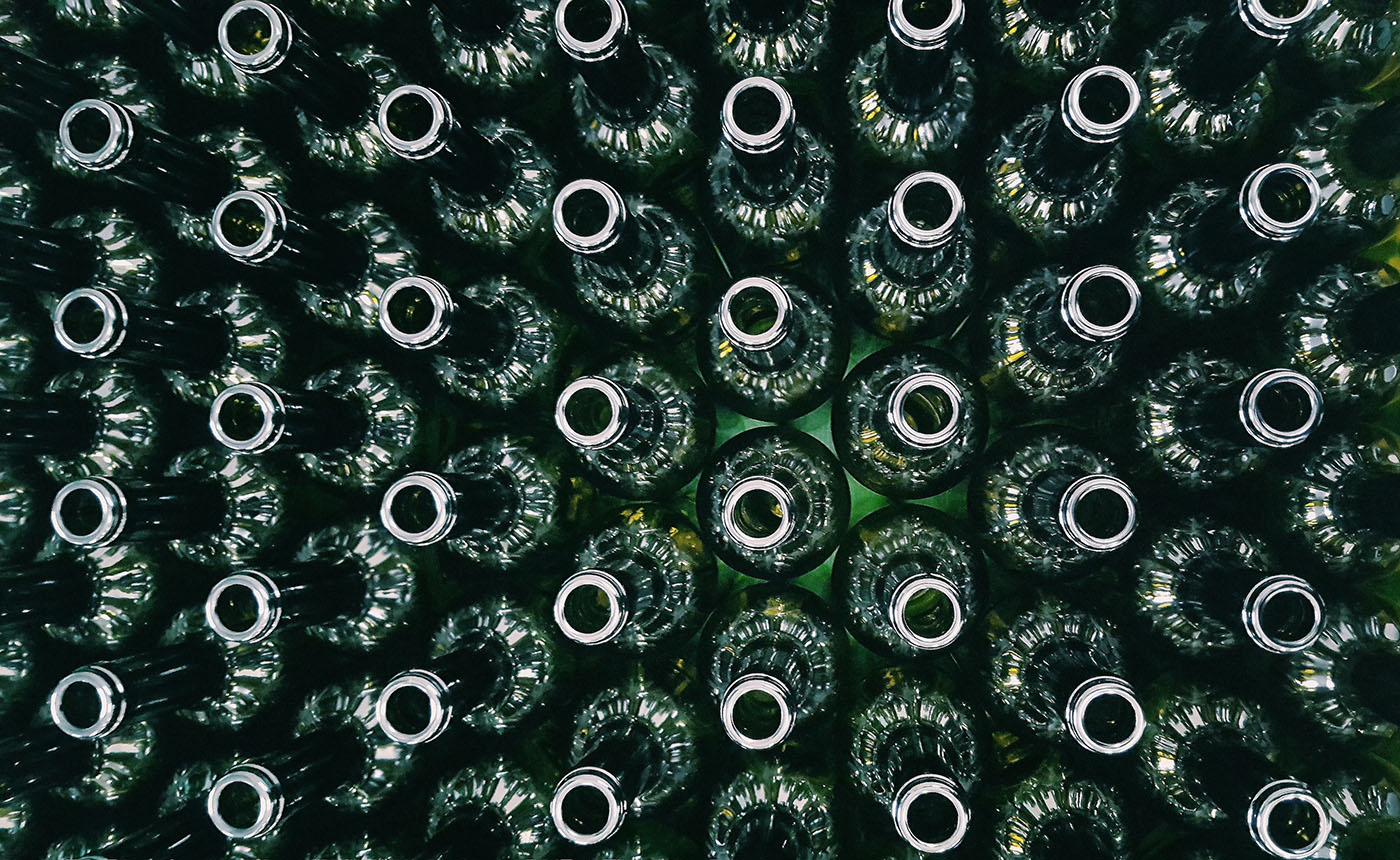

QUALITY CONTROL SYSTEM FOR EMPTY GLASS BOTTLES

Project background:

The client often received defective glass containers from the supplier. The quality control person was not always able to spot the defective bottles during the production process and remove them from the conveyor line. The defective product was therefore put on the shelves of shops, which resulted in complaints from shoppers.

Biggest challenges:

Quality defects in glass bottles are difficult to detect because of material transparency, light refraction makes microcracks and bubbles hard to distinguish. In addition, optical illusions and lighting effects can mask damage. The variety of defects and the high speed of the production conveyor line make this solution even more challenging.

Solution:

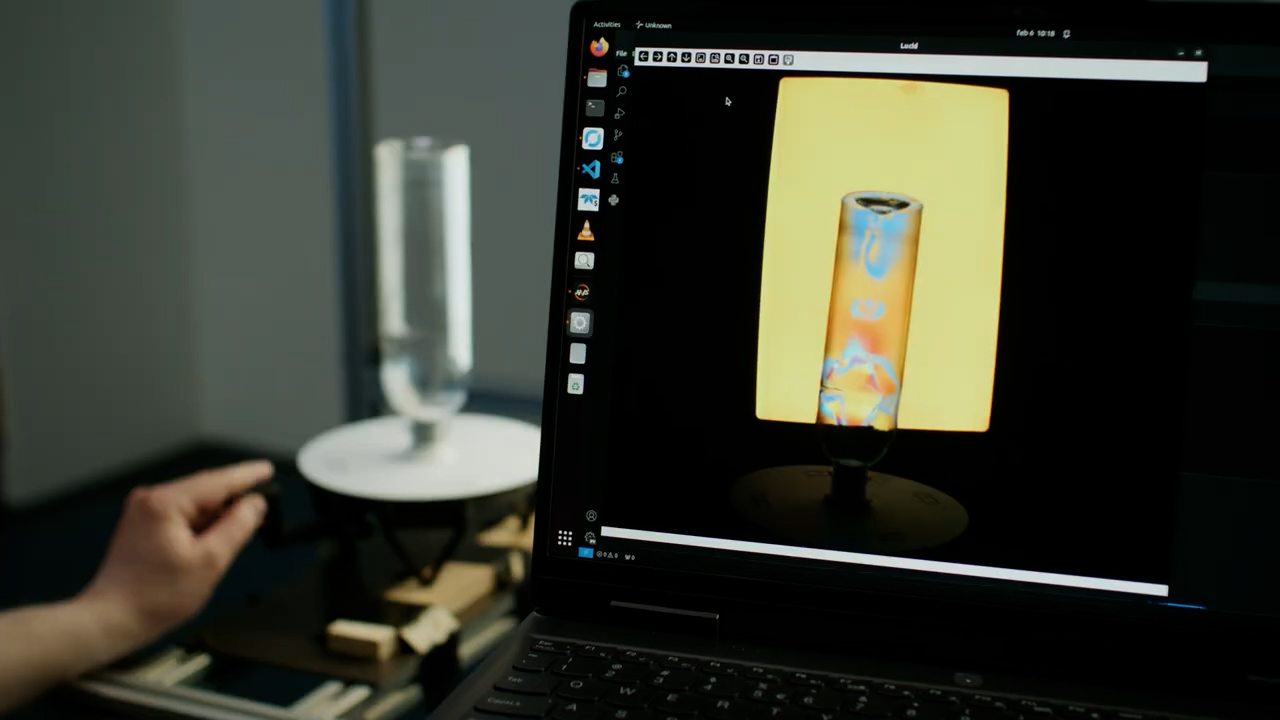

Developed an automated system which detects bottle defects without human intervention, by using a computer vision solutions. System can detect following defects:

- cracks,

- scratches on the walls of the glass bottle,

- defects of bottle neck,

- rinse residue,

- and other contaminants.

Project involved developing and installing a prototype device on a filling line. The deviceconsists of the following components: control panel, handling process, administration system, physical quality inspection unit using a unique mirror system, three cameras, bottle detection sensors, and bottle separation inspection stage which physically redirects defective bottles to a separate conveyor belt.

Key benefits:

- Optimised costs and speed of production processes;

- Reduced time to extract and process quality data;

- Human error eliminated.