AUTOMATED QUALITY CONTROL SYSTEM FOR TEXTILE PRODUCTS

Project background:

Production process of textile products currently involves manual quality control, and client is interested in automating this step.

Biggest challenges: highly unpredictable environment to analyse – products overlapping each other, folded in different ways, many different potential design solutions.

Solution:

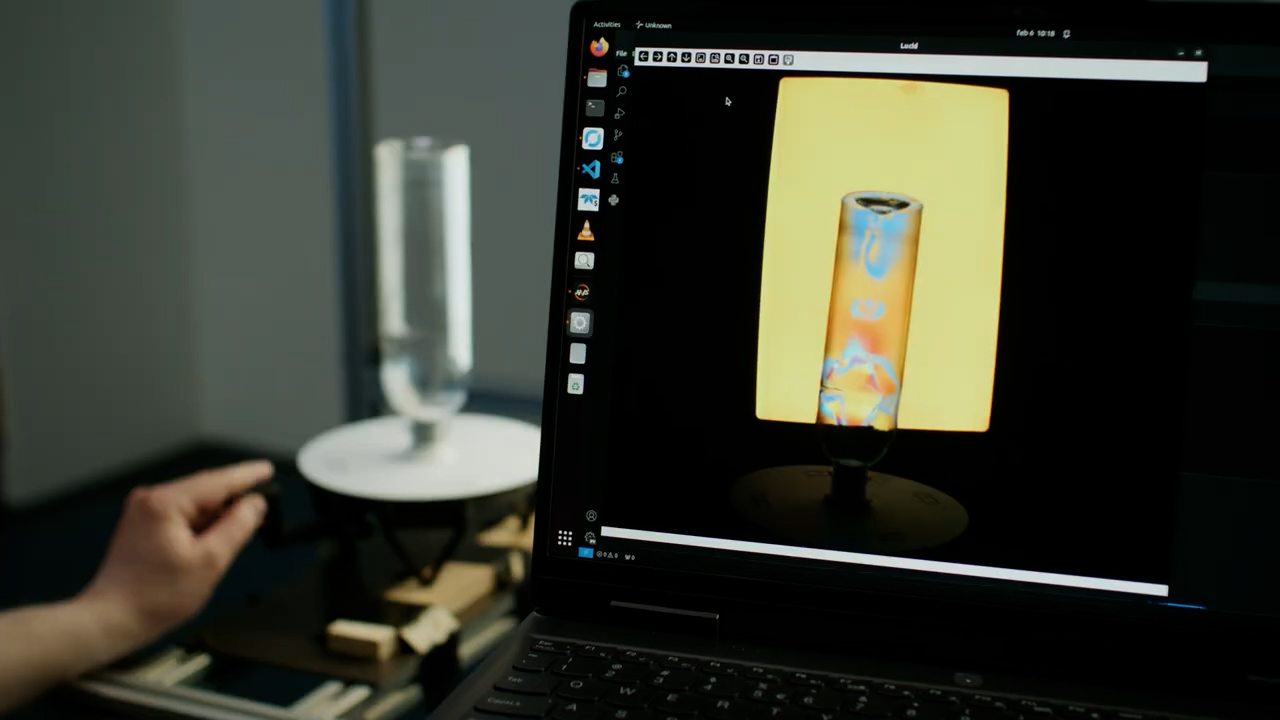

Automated textile quality control system has been developed to identify the brand, size, color, and printed design elements of textile products. It also compares this data with specified order parameters.

Customized system for result visualization was developed and integrated with client’s business management systems and database. Computer vision and machine learning solutions were used. Visual data processing takes place in real time.

Key benefits:

- Improved production process;

- Improved quality control time and efficiency;

- Optimised workforce costs.