GlassCon

We are proud to announce that work on GlassCon, one of the most innovative technologies in the manufacturing industry, has been completed. We have been working on the project with enthusiasm throughout the year, attracting Valmiermuiža Brewery and the Latvian Electronic and Optical Equipment Industry Competence Center as partners in the research and experimental development phase.

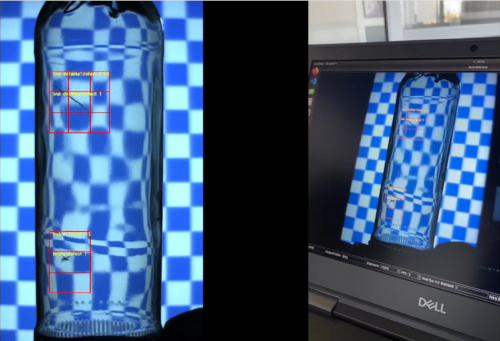

GlassCon is a fully automated, new type of equipment for quality control of glass containers, including bottles, jars, etc. Powerful computer vision technology detects the slightest defects, allowing them to be fixed immediately.

The GlassCon system can be trained to perform a variety of visual analysis tasks. It can monitor:

-the level of filling of the bottles;

-cracks or scratches in the walls of the glass container;

-glass container neck defects;

-the presence of residues of rinsing and other unwanted liquid;

-cork conformity and defects;

-the location, skew or defects of the label;

-the conformity of the label with the contents of the glass container;

-the specificity of the brand features, such as the logo, the non-standard shape;

-determination of the amount of foam in liquids,

as well as several other steps required for a perfect result. When a defect or non-conformity is detected, the system immediately signals the actuator. The defective product is diverted from the production line without shutting down the plant and causing significant losses.

GlassCon is adaptable to the needs of a wide range of manufacturers. It can be used on an existing production line. GlassCon is also available to small food producers. Due to its compact size and high moisture resistance, it can be installed in almost any condition.

The main goal of the project was to create an economically affordable quality control technology for glass containers and to expand control possibilities. Today, we can say with satisfaction that we have succeeded in creating an unprecedented solution on the market that will make the work for food producers much easier.

We are proud to announce that work on GlassCon, one of the most innovative technologies in the manufacturing industry, has been completed. We have been working on the project with enthusiasm throughout the year, attracting Valmiermuiža Brewery and the Latvian Electronic and Optical Equipment Industry Competence Center as partners in the research and experimental development phase.

GlassCon is a fully automated, new type of equipment for quality control of glass containers, including bottles, jars, etc. Powerful computer vision technology detects the slightest defects, allowing them to be fixed immediately.

The GlassCon system can be trained to perform a variety of visual analysis tasks. It can monitor:

-the level of filling of the bottles;

-cracks or scratches in the walls of the glass container;

-glass container neck defects;

-the presence of residues of rinsing and other unwanted liquid;

-cork conformity and defects;

-the location, skew or defects of the label;

-the conformity of the label with the contents of the glass container;

-the specificity of the brand features, such as the logo, the non-standard shape;

-determination of the amount of foam in liquids,

as well as several other steps required for a perfect result. When a defect or non-conformity is detected, the system immediately signals the actuator. The defective product is diverted from the production line without shutting down the plant and causing significant losses.

GlassCon is adaptable to the needs of a wide range of manufacturers. It can be used on an existing production line. GlassCon is also available to small food producers. Due to its compact size and high moisture resistance, it can be installed in almost any condition.

The main goal of the project was to create an economically affordable quality control technology for glass containers and to expand control possibilities. Today, we can say with satisfaction that we have succeeded in creating an unprecedented solution on the market that will make the work for food producers much easier.